A closed loop is sometimes considered a second-class citizen in the world of water treatment. As the name suggests, a closed cooling or heating loop is self-contained, piped and sealed off from the air or evaporative processes. The same water or thermal fluid can be recirculated through the system for weeks, months, even years in some cases.

As such, closed loops are not susceptible to the threats caused by open air exposure, as in a cooling tower. Because of this, facility teams often take an “out-of-sight, out-of-mind” approach to their maintenance. Even water treaters sometimes give closed loops less attention since they represent a lower risk, and lower dollar opportunity. “Do we have enough glycol?” might be the only question asked over a full twelve months of operation.

Does this hands-off approach pay off? Not if you’re keeping tabs on your energy bills. Apart from premature repairs or replacement, a neglected closed loop will eventually become a monthly drain on your energy usage that only gets worse as time goes on.

Fortunately, there are some relatively simple steps you can take to recapture the efficiency of your closed heating or cooling system. Here are five practical things you can do:

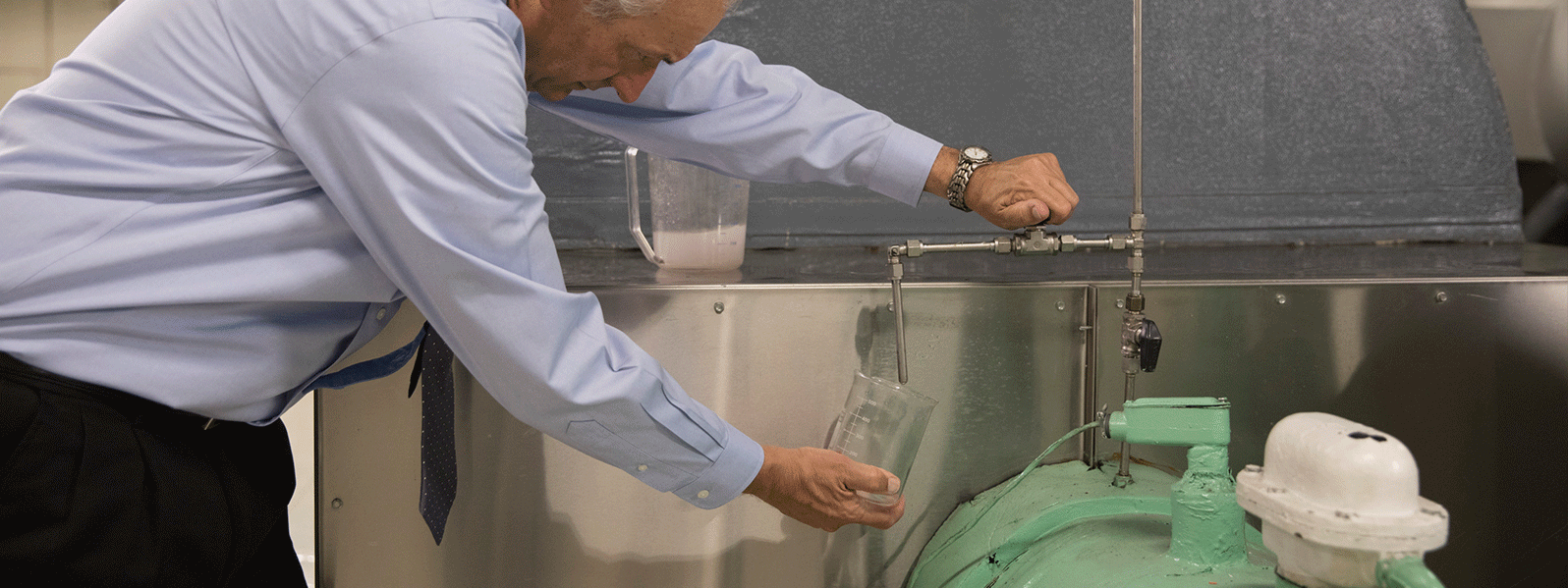

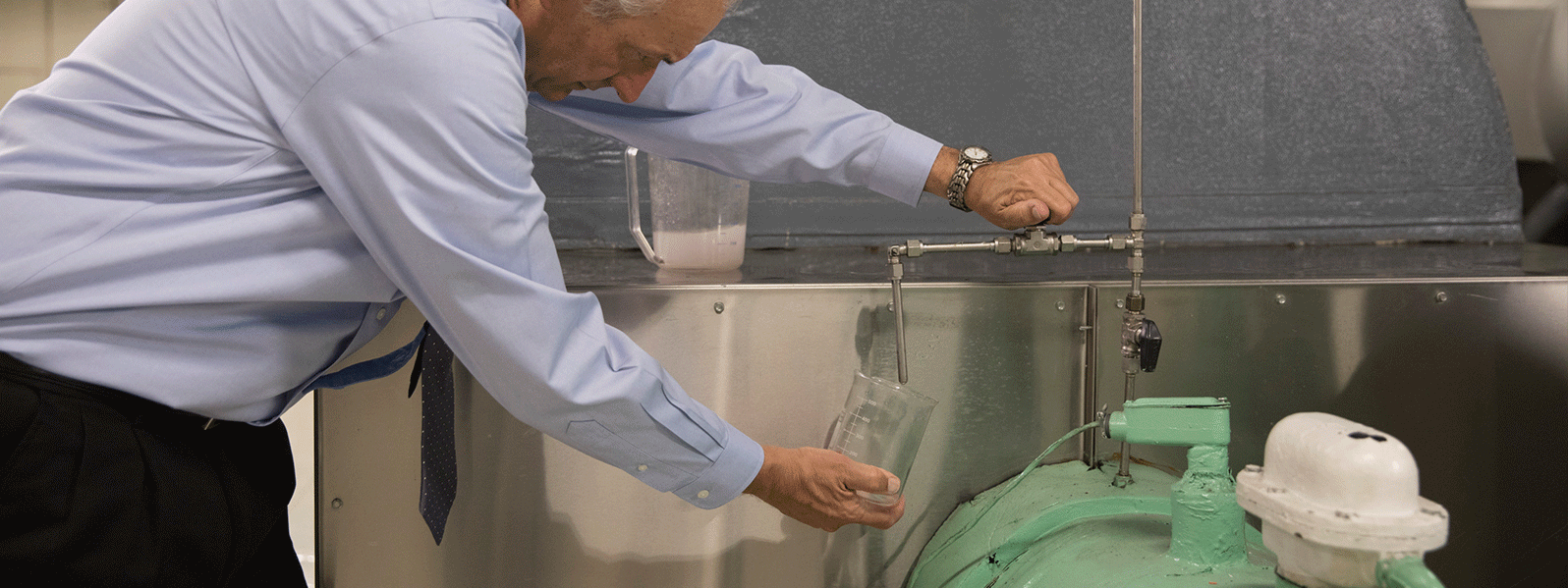

1. Look at your water

Okay, that sounds highly unscientific, but in the case of a closed loop, a regular visual inspection can be telling. If your water looks normal, it may or may not be – only a test will tell. But if it looks bad, it almost always is. A closed loop changes out its fluid infrequently, so a corroded or fouled system recirculates accumulated by-product, discoloring the water. If it looks or smells bad, get it tested to find out why.

2. Know your makeup water volume and source chemistry

You might be surprised at how many facility teams couldn’t tell you how much water is used by any one system, and many can’t tell you what’s in their water. Both of these basic facts play a key role in keeping your boiler or chilled loop running at peak efficiency.

Volume, or water usage, determines the ideal feed rate of your corrosion-inhibitor and biocide. The chemical profile of your source water determines the specific formulas you should use, and the ideal ratio of inhibitor to biocide. Without this baseline knowledge, it’s really just a guessing game.

3. Get rid of solids

Unwanted solids, like iron oxide, calcium hardness or remains of bio activity, rob your system of thermal efficiency. If left unchecked, this debris will continue to increase and disrupt the heat transfer surfaces so your system has to run harder to produce the same result. Not only does this increase your energy bills, it puts extra stress on costly system components, increasing the likelihood of repairs and downtime down the road.

A good treatment program can help stabilize and control the levels of contaminants. Depending on the chemistry of your source water, pretreatment or filtration may be needed. A water softener can reduce iron content, and a reverse osmosis system removes a whole spectrum of solids. Side-stream filtration is another possible alternative.

If your water testing indicates a solids problem, be sure to talk to your water treater. At HOH, we have a dedicated team who can help you implement cost-effective pretreatment solutions.

4. Control your microbiological activity

Bacteria is stubborn; it can grow in water temperatures between 0° and 160°F. Anaerobic organisms, such as sulfate-reducers, can reproduce even with no oxygen present in your closed loop. And if there is oxygen, you’ll need to address the resulting aerobic activity.

What is the problem with bacteria? For one, they happen to break down common corrosion inhibitors, reducing the effectiveness of the treatment you’re relying on (and paying for) to protect critical metal components. Similar to solids, bacteria also disrupts the efficient transfer of heat from coil to water. Getting your biological activity under control with the right biocide is key to closed loop performance.

5. Get a lab analysis

Regular field testing of your water is important to check basic water quality metrics. But this should be supplemented by a more in-depth lab analysis at least once a year. The chemical makeup of your source water can change over time, and a full lab work-up will give you an up-to-date picture of where you sit, and you can trend key measurements over time. The more you know about your water profile, the more you can fine tune it to maximize your closed loop efficiency and longevity.

While it may be tempting to just let your closed loop cooling or heating systems run on auto-pilot, some common-sense care can pay bigger dividends than what is commonly assumed. These measures don’t have to break your budget or eat up man-hours, but they do have to be performed consistently. A quality water treatment partner can help keep things manageable for you and your team.

If you’d like more information about closed loop care, feel free to reach out to your HOH water quality engineer or contact our technical services department Contact HOH Water Technology | HOH Water Technology.

If you’ve never had your closed loop water tested, that’s a good first step. Our initial site survey includes water sampling and testing, providing you a first baseline picture of your water quality.

Recent Blog Posts

Five Ways to Increase the Efficiency of Your Closed Loop System

Global 6K for Water