Because they work so hard and there’s a slim margin for error, it’s important to have year-round awareness of the condition of your cooling towers. Regular cleaning and disinfection will help prevent and/or mitigate clogging, scaling, corrosion, or even contamination of bacteria or water-borne pathogens. Below are the three types of chemical cleaning that will keep things running efficiently and safely– especially during the high-demand season.

Cooling Towers & Chemical Cleaning

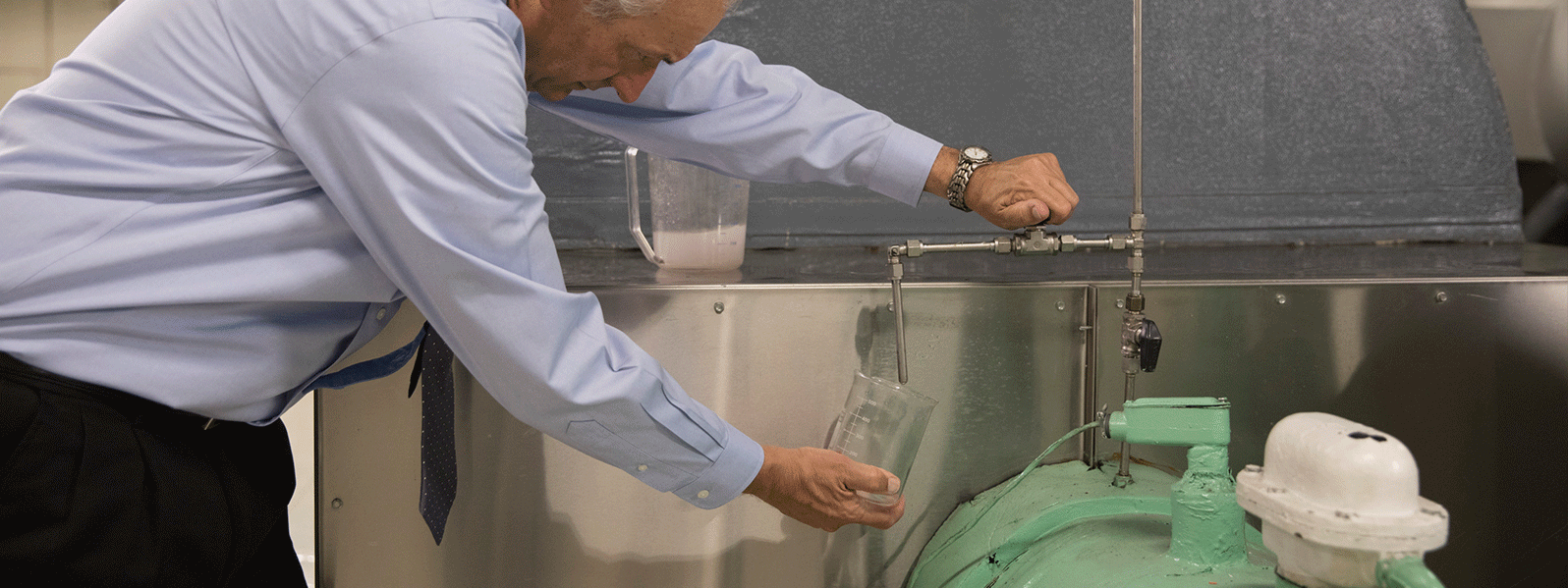

Before we discuss the specifics of chemical cleaning you should know that cooling towers can be cleaned either by mechanical or chemical methods. Mechanical cleaning involves power washing with professional equipment and chemical cleaning comes in the three forms that we’ll explore below.

Pro Tip: Make sure to do a thorough inspection and clear any debris out of your towers before cleaning them.

1. Acid Cleaning

What is it?

The application of acid(s) to dissolve common scale deposits such as iron oxide and calcium carbonate.

Who needs it:

- Facilities that have neglected maintenance of their towers for more than a few seasons

- Facilities that are experiencing decreased cooling tower performance and reduced heat transfer and heat rejection

- Plants that have been shut-down from the equipment not being able to maintain the temperature

What to expect:

An assessment of your water will be performed to determine what kind of deposits you’re getting and inform your water treater as to which type of acid product will be needed to reduce the scale.

Due to the aggressive nature of acids, acid cleaning always involves a compromise between dissolving scale and protecting the system’s metallurgy.

Your water treater will have to be diligent about disposal and discharge of the spent solution. They must follow all federal, state, and local laws as they pertain to discharging low-pH water.

Pro Tip: Prior to conducting an acid cleaning, make sure all required Personal Protective Equipment (PPE) is on-site, readily available, and in good working condition. Also, contact your facility’s safety director to ensure all protocols are followed.

2. Dispersant Cleaning

What is it?

Dispersant cleaning helps to remove accumulated silt, loose scale, and biofilm and makes a disinfection procedure more thorough and effective. This type of cleaning is the easiest and safest method, although it will not remove hard mineral scale or rust from the system.

Who needs it:

- Facilities where water has been stagnant for more than two weeks

- Any facility operating without a proper water treatment program

- Any facility whose system water tested above the threshold limit for Legionella bacteria

- Facilities that have recently experienced high head pressure and low cooling capacity

- Facilities with visibly fouled towers (basin walls are slimy, has a foul odor, the water is murky).

What to expect:

The cleaning product is slug-dosed into the system and allowed to circulate for at least several hours, and possibly overnight. The system is then drained and flushed, and the process may be repeated, alternating between a bio-dispersant and a mud-and-silt dispersant.

For a heavily-fouled system or a system that sees continuous fouling for whatever reason, your facility might need a regular dispersant clearing. An oxidizing biocide can also be incorporated into this procedure, with biocide added a couple of hours after each dispersant addition.

Pro Tip: Your water treatment partner should provide a detailed procedure for your system so you can understand the process and replicate it on your own if needed.

3. Disinfection

What is it?

Disinfection remediates waterborne pathogens that have grown due to fouling or neglect. It is the most potent measure you can take against bio-growth when something beyond Dispersant Cleaning is needed. Many systems benefit from an annual disinfection to prevent issues caused by accumulated growth.

Pro Tip: Because of recent rules as they pertain to Legionella risk control, it is extremely important to follow proper protocol for disinfection of your system.

Who needs it:

Biocide disinfection is recommended if your system…

- Has been stagnant for more than two weeks

- Has been neglected or operated without a proper water treatment program

- Tested above the threshold limit for Legionella bacteria

- Has recently experienced high head pressure and low cooling capacity,

- Is visibly fouled (basin walls are slimy, has a foul odor, the water is murky).

What to expect:

The water treater will recommend and/or apply an appropriate plan for disinfection that could include one or all of the three cleaning methodsodalities in this post.

After disinfection is completed, a validation step should be performed to confirm that the system is ready to return to normal operation.

Cooling Towers Are A Year-Round Initiative

If you’re really pressed for time you can treat your cooling towers as you would a summer-only cottage – clean it when you shut it down and clean it when you open it up. But ideally, if you want your cooling towers to stay clean, safe, and efficient, you’ll need to conduct regular inspections and then perform an opening, closing, and mid-year physical cleaning.

An experienced water treatment partner should guide you along the way to make sure that you’re performing cleaning correctly and at regular intervals.

Remember, HOH is always here to help.

Recent Blog Posts

Five Ways to Increase the Efficiency of Your Closed Loop System

Global 6K for Water