Have you noticed an increase in water treatment costs recently? Underserved equipment may be to blame. From skyrocketing energy costs to increase in chemicals used to chemically balance the water, a battery of water tests in a lab and an inspection of your equipment should shed light on the reduction in water efficiency.

Have you noticed an increase in water treatment costs recently? Underserved equipment may be to blame. From skyrocketing energy costs to increase in chemicals used to chemically balance the water, a battery of water tests in a lab and an inspection of your equipment should shed light on the reduction in water efficiency.

Treating Causes or Symptoms?

If you take a quick reading and notice the alkalinity out of sorts, is your first reaction to add chemicals to rebalance your water, or do you take the time to see what may be influencing your waters’ chemical composition? Simply throwing in additional chemicals will change the water, but it may not be a “one-and-done” scenario, and you’ll likely spend more on chemicals in the long run.

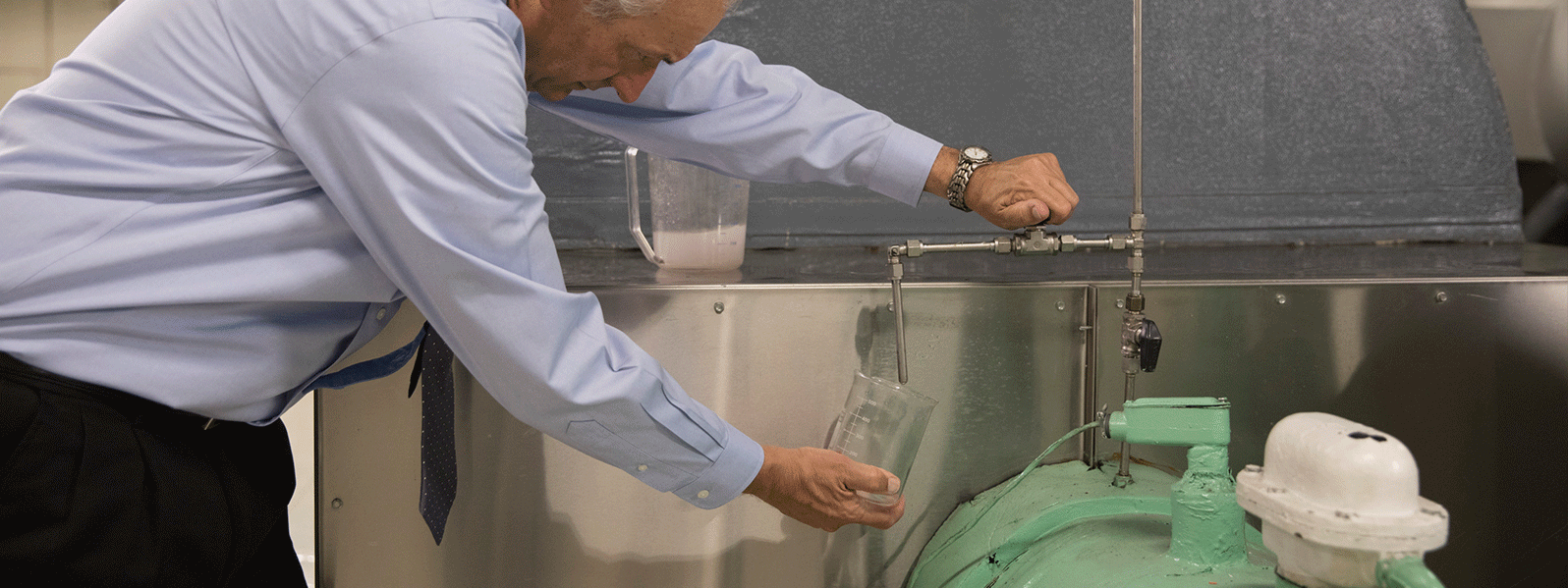

Instead, bring in a water treatment professional to inspect your equipment and take water samples for evaluation. A water treatment company with a full lab can quickly identify in more detail, issues with your current water chemical regimen, the equipment, or if your own testing methods are inaccurate. The goal is to use the minimal amount of chemical necessary for your water – increasing water efficiency.

Assess Cycles of Concentration

It may sound counterintuitive, but increasing your cycles may decrease your cost in both water makeup flow and bleed flow, which in turn reduces cost of chemicals. Similar to the lab and chemical assessment, ask your water treatment company rep to audit your equipment in order to discover the right cycle count to maximize your savings.

Seasonal Adjustments with Chemical Dosage

As water warms, it becomes a more welcoming host to bacteria, mold, and fungus, which requires a higher dosage of biocide to keep growth down. Maintaining the same concentration of biocide year-round does not make sense in the northern half of the country, as cooler water slows growth.

Regular Inspections for Water Efficiency

Scaling and corrosion on condensers and cooling towers decrease water efficiency and add wear and tear to your equipment. Ask your water treatment partner to demonstrate proper inspection techniques for your equipment, and invite them into your facility for thorough inspections on a regular interval.

Regardless of your comfort level with your facility’s water system, it’s advisable to bring your water treatment representative in to walk through maintenance best practices and help with servicing your equipment.

Recent Blog Posts

Five Ways to Increase the Efficiency of Your Closed Loop System

Global 6K for Water