Delaying or ignoring proper winterization for your cooling systems can cause a host of problems including unsafe work conditions, broken equipment, higher energy bills, and even code violations. Your cooling system needs specific care before shutdown or lay-up. First let’s look at how winter messes with your system.

Delaying or ignoring proper winterization for your cooling systems can cause a host of problems including unsafe work conditions, broken equipment, higher energy bills, and even code violations. Your cooling system needs specific care before shutdown or lay-up. First let’s look at how winter messes with your system.

Winter Threats to Cooling Systems

Without proper shutdown, your equipment can become a breeding ground for these common offenders:

- Metal Corrosion

- Microbiologically Induced Corrosion (MIC)

- Bacteria (Legionella)

- Scaling

- Fouling

- Rust

And those water issues can cause the following damage to your cooling equipment, and your facility:

- Untimely equipment downtime

- Broken coils and burst pipes

- Plugged equipment

- Treatment program issues in subsequent years

Failure to prepare your systems for winter can also put the people in your facility at risk for these safety concerns:

- Unhealthy temperatures in the facility making people sick

- Putting people on icy roofs to troubleshoot during the winter

- Bacteria and mold growth (such as Legionella)

- Poor air quality in facility causing illness or breathing trouble

Now let’s look at the tasks and timeline for proper winterization.

Prepping Industrial Cooling Systems For Winter and Low-Load Season

For much of the United States, where cooling systems will be completely shut down during winter months, we recommend downloading our 3-Step Winterization Checklist so you can prep your systems properly. For locations that will run systems at low load, you’ll still want to follow the cleaning process outlined in Step 2 on that checklist.

No matter where you’re located, you’ll want to work with a professional water treater to develop a winterization strategy customized for your facility, document it, and follow it every year.

Your winterization strategy should include, but is not limited to, the following:

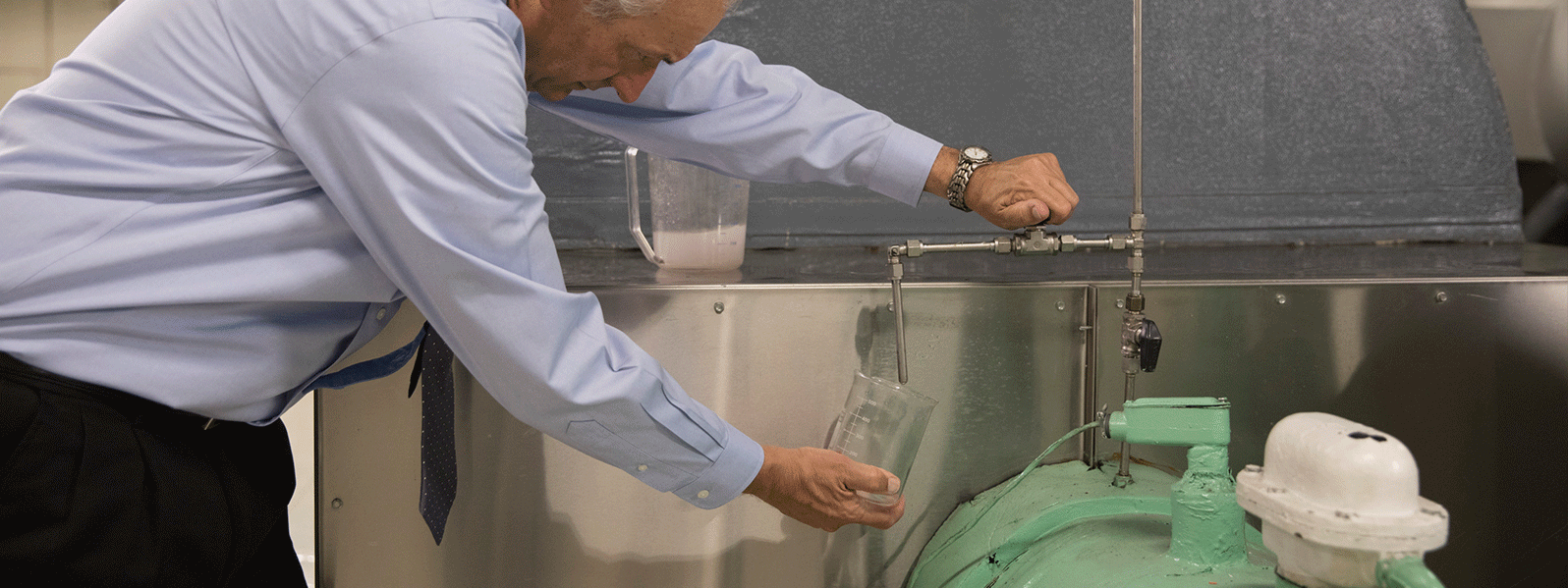

- A complete system checkup, including testing controls and water testing

- Open systems cleaning, disinfection, and passivation

- Plan to insulate and heat trace pipes and sprinklers

- Introduce anti-freeze to systems that will remain exposed to the cold

- Temperature control of your towers and mechanical rooms

- Weather stripping doors and windows

Start Your Cooling System Winterization Process

While we advise that you follow maintenance best practices for cooling water systems all year round, you’ll need to prioritize your efforts early in the fall to focus on winterization tasks.

Our Technical Director, Darius Barkauskas, weighed in on the ideal timeline:

“In northern climates, this conversation should start mid to late September. Typically the lay-up of systems is weather dependent but usually takes place in October. The process should be conducted at the end of year operation for systems that will be shut down for the winter. For systems that will continue to operate through the winter, the process should still be performed before continuing treatment during the winter months.”

For facilities in places like Florida or Arizona that do not shut down entirely, Barkauskas recommends:

“For systems that will continue to run through the winter, the process should still be done to provide an end of year cleaning, disinfection, and passivation followed by continuing treatment programs. Systems that will be winterized with anti-freeze or glycol… that is also weather dependent, but typically happens between mid-October through December. The conversation can happen in conjunction with the lay-up process.”

When prioritizing your fall tasks, start here:

- Identify if you’re running ethylene glycol or propylene through your building’s hot and chilled water systems

- Test your water

- Clean, disinfect, and passivate open systems such as cooling towers

- Estimate the amount of corrosion inhibitor that is needed

- Add it to your system in the proper amounts

HOH specializes in helping facilities with their winterization procedures and we offer preventative maintenance programs led by an HOH specialist who will set you up for success.

Barkauskas emphasizes:

“The biggest mistake is not performing an annual cleaning and winterization process because it can cause issues over the winter months and will lead to challenges in subsequent cooling seasons. Often there is a short time window operationally to perform your winterization process. We encourage facilities to call us first, so we can make sure it’s done right.”

Don’t delay your winterization process. Contact us to get started today.

Recent Blog Posts

Five Ways to Increase the Efficiency of Your Closed Loop System

Global 6K for Water